The Power of Tinned Copper Cables A Comprehensive Guide to Tinned Copper Power Cables

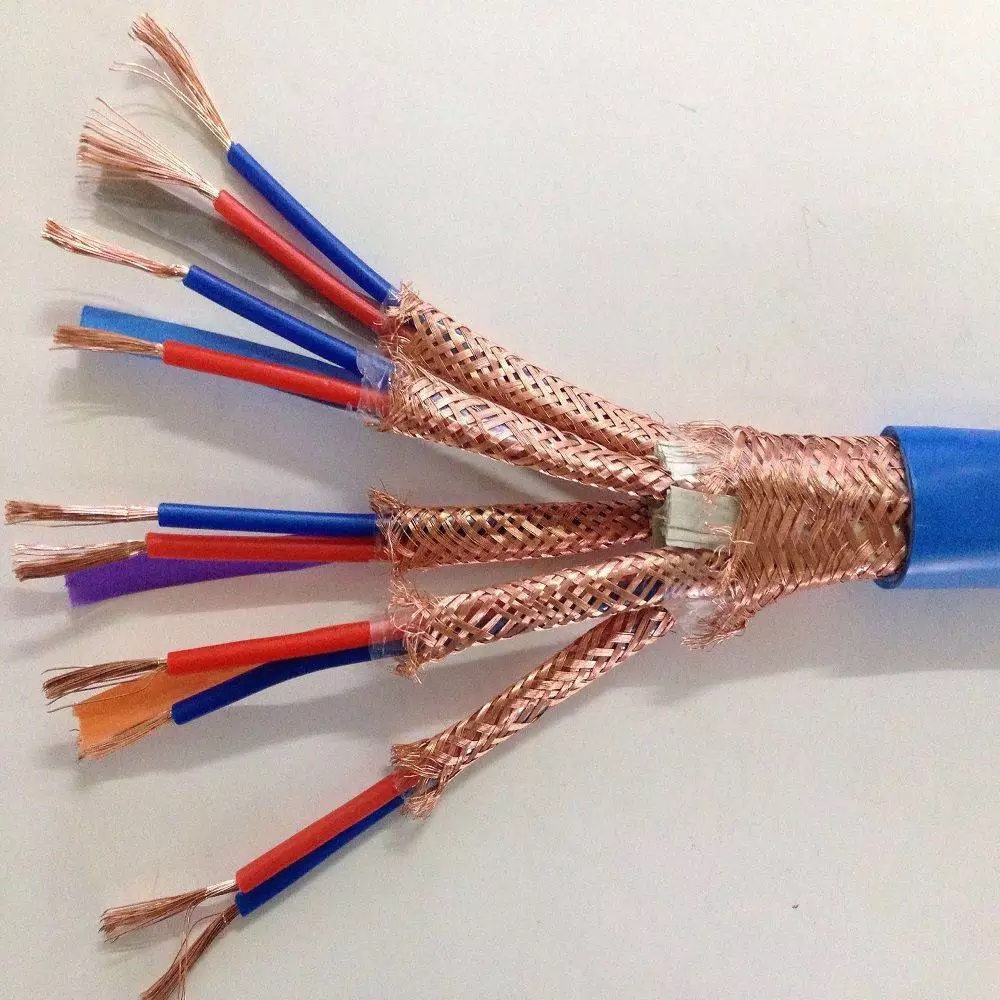

Introduction In the world of electrical wiring, tinned copper cables play a crucial role in ensuring the safe and efficient transmission of power. These cables are widely used in various industries and applications due to their unique properties and benefits. One of the most popular types of tinned copper cables is the tinned copper power cable, which offers superior conductivity, corrosion resistance, and durability. In this comprehensive guide, we will explore the features, advantages, applications, and installation considerations of tinned copper power cables. 1. What are Tinned Copper Power Cables? Tinned copper power cables are electrical cables that are made of copper conductors coated with a thin layer of tin. This tinning process involves applying a coating of molten tin to the surface of the copper conductor, which helps enhance the cable's performance and durability. The tinning of copper cables is done to protect the copper from corrosion, improve solderability, and enhance the overall conductivity of the cable. 2. Features of Tinned Copper Power Cables Tinned copper power cables offer a wide range of features that make them a popular choice for various power transmission applications. Some of the key features of tinned copper power cables include: – Superior conductivity: Copper is known for its excellent electrical conductivity, and tinning the copper conductors further enhances this property. The thin layer of tin on the copper surface helps reduce oxidation and corrosion, ensuring consistent and reliable conductivity over time. – Corrosion resistance: The tin coating on tinned copper cables provides an additional layer of protection against corrosion and oxidation. This makes tinned copper power cables ideal for use in harsh environments where exposure to moisture, chemicals, or other corrosive elements is a concern. – Flexibility: Tinned copper power cables are highly flexible, making them easy to install and handle in various applications. The flexibility of these cables allows for easier routing and termination, reducing installation time and effort. – High temperature resistance: Tinned copper power cables are designed to withstand high temperatures, making them suitable for use in applications where heat resistance is essential. The tin coating helps improve the cable's thermal performance and ensures stable operation even in extreme temperature conditions. – Durability: Tinned copper power cables are durable and long-lasting, thanks to the protective tin coating that helps prevent damage and wear over time. These cables are designed to withstand mechanical stress, bending, and other environmental factors, ensuring reliable performance throughout their lifespan.  3. Advantages of Tinned Copper Power Cables Tinned copper power cables offer several advantages over traditional copper cables, making them a preferred choice for many power transmission applications. Some of the key advantages of tinned copper power cables include: – Enhanced conductivity: The tin coating on tinned copper cables improves the cable's conductivity, resulting in lower resistance and improved power transmission efficiency. This enhanced conductivity helps reduce energy loss and ensures optimal performance in electrical systems. – Improved solderability: Tinned copper power cables are easier to solder and terminate due to the presence of the tin coating. The tin layer provides a smooth and uniform surface for soldering, ensuring secure connections and reliable electrical contact. – Reduced maintenance costs: Tinned copper power cables are highly resistant to corrosion and oxidation, reducing the need for frequent maintenance and replacements. The durable construction of these cables helps lower maintenance costs and ensures long-term reliability in power transmission systems. – Environmental protection: The tin coating on tinned copper cables provides an additional layer of environmental protection, making the cables suitable for outdoor and underground installations. The corrosion resistance of tinned copper power cables helps prevent environmental damage and ensures safe and reliable operation in various conditions. – Wide range of applications: Tinned copper power cables are versatile and can be used in a wide range of applications, including power distribution, industrial machinery, renewable energy systems, and more. These cables are suitable for both indoor and outdoor installations, making them a flexible solution for diverse electrical projects. 4. Applications of Tinned Copper Power Cables Tinned copper power cables are used in a variety of applications across different industries due to their superior performance and reliability. Some common applications of tinned copper power cables include: – Power distribution: Tinned copper power cables are widely used in power distribution systems to transmit electrical power from the source to various loads. These cables are designed to handle high currents and voltages efficiently, making them essential components in power distribution networks. – Industrial machinery: Tinned copper power cables are ideal for use in industrial machinery and equipment where reliable power transmission is critical. These cables can withstand the rigors of industrial environments and provide consistent power supply to drive motors, pumps, and other machinery. – Renewable energy systems: Tinned copper power cables are commonly used in renewable energy systems such as solar panels and wind turbines. The superior conductivity and durability of these cables make them well-suited for connecting solar arrays, inverters, and other components in renewable energy installations. – Marine and offshore applications: Tinned copper power cables are suitable for marine and offshore applications where exposure to saltwater and harsh conditions is a concern. The corrosion resistance of these cables makes them ideal for use on ships, oil rigs, and other marine structures. – Data centers: Tinned copper power cables are used in data centers to provide reliable power distribution for servers, networking equipment, and other critical infrastructure. The high conductivity of these cables helps ensure efficient power delivery to support the demanding requirements of data center operations. 5. Installation Considerations for Tinned Copper Power Cables When installing tinned copper power cables, it is important to consider several factors to ensure proper performance and safety. Some key installation considerations for tinned copper power cables include: – Cable sizing: Properly sizing the tinned copper power cables according to the current carrying capacity and voltage requirements of the application is essential to prevent overheating and ensure safe operation. Consultation with a qualified engineer or electrician can help determine the appropriate cable size for the specific installation. – Cable routing: Careful consideration should be given to the routing of tinned copper power cables to avoid sharp bends, excessive pulling, or other stress-inducing conditions. Proper cable routing helps prevent damage to the cables and ensures optimal performance over time. – Termination methods: When terminating tinned copper power cables, use appropriate methods such as soldering, crimping, or compression connectors to ensure secure and reliable connections. Improper termination can lead to poor conductivity, overheating, and potential safety hazards. – Environmental conditions: Consider the environmental conditions in which the tinned copper power cables will be installed, such as temperature, moisture, and exposure to chemicals. Choose cables with the appropriate insulation and jacketing materials to withstand the specific environmental factors and ensure long-term reliability. – Compliance with standards: Ensure that the installation of tinned copper power cables complies with relevant industry standards and regulations to guarantee safety and performance. Following insulated sheathed power cable and guidelines helps prevent accidents, fire hazards, and other risks associated with electrical installations. Conclusion Tinned copper power cables are essential components in modern electrical systems, offering superior conductivity, corrosion resistance, and durability for various power transmission applications. These cables provide numerous advantages over traditional copper cables, making them a preferred choice for industries such as power distribution, industrial machinery, renewable energy, and more. By understanding the features, advantages, applications, and installation considerations of tinned copper power cables, electrical professionals can make informed decisions when selecting and installing these cables for their projects. With their exceptional performance and reliability, tinned copper power cables continue to play a vital role in ensuring safe and efficient power transmission in today's interconnected world.

3. Advantages of Tinned Copper Power Cables Tinned copper power cables offer several advantages over traditional copper cables, making them a preferred choice for many power transmission applications. Some of the key advantages of tinned copper power cables include: – Enhanced conductivity: The tin coating on tinned copper cables improves the cable's conductivity, resulting in lower resistance and improved power transmission efficiency. This enhanced conductivity helps reduce energy loss and ensures optimal performance in electrical systems. – Improved solderability: Tinned copper power cables are easier to solder and terminate due to the presence of the tin coating. The tin layer provides a smooth and uniform surface for soldering, ensuring secure connections and reliable electrical contact. – Reduced maintenance costs: Tinned copper power cables are highly resistant to corrosion and oxidation, reducing the need for frequent maintenance and replacements. The durable construction of these cables helps lower maintenance costs and ensures long-term reliability in power transmission systems. – Environmental protection: The tin coating on tinned copper cables provides an additional layer of environmental protection, making the cables suitable for outdoor and underground installations. The corrosion resistance of tinned copper power cables helps prevent environmental damage and ensures safe and reliable operation in various conditions. – Wide range of applications: Tinned copper power cables are versatile and can be used in a wide range of applications, including power distribution, industrial machinery, renewable energy systems, and more. These cables are suitable for both indoor and outdoor installations, making them a flexible solution for diverse electrical projects. 4. Applications of Tinned Copper Power Cables Tinned copper power cables are used in a variety of applications across different industries due to their superior performance and reliability. Some common applications of tinned copper power cables include: – Power distribution: Tinned copper power cables are widely used in power distribution systems to transmit electrical power from the source to various loads. These cables are designed to handle high currents and voltages efficiently, making them essential components in power distribution networks. – Industrial machinery: Tinned copper power cables are ideal for use in industrial machinery and equipment where reliable power transmission is critical. These cables can withstand the rigors of industrial environments and provide consistent power supply to drive motors, pumps, and other machinery. – Renewable energy systems: Tinned copper power cables are commonly used in renewable energy systems such as solar panels and wind turbines. The superior conductivity and durability of these cables make them well-suited for connecting solar arrays, inverters, and other components in renewable energy installations. – Marine and offshore applications: Tinned copper power cables are suitable for marine and offshore applications where exposure to saltwater and harsh conditions is a concern. The corrosion resistance of these cables makes them ideal for use on ships, oil rigs, and other marine structures. – Data centers: Tinned copper power cables are used in data centers to provide reliable power distribution for servers, networking equipment, and other critical infrastructure. The high conductivity of these cables helps ensure efficient power delivery to support the demanding requirements of data center operations. 5. Installation Considerations for Tinned Copper Power Cables When installing tinned copper power cables, it is important to consider several factors to ensure proper performance and safety. Some key installation considerations for tinned copper power cables include: – Cable sizing: Properly sizing the tinned copper power cables according to the current carrying capacity and voltage requirements of the application is essential to prevent overheating and ensure safe operation. Consultation with a qualified engineer or electrician can help determine the appropriate cable size for the specific installation. – Cable routing: Careful consideration should be given to the routing of tinned copper power cables to avoid sharp bends, excessive pulling, or other stress-inducing conditions. Proper cable routing helps prevent damage to the cables and ensures optimal performance over time. – Termination methods: When terminating tinned copper power cables, use appropriate methods such as soldering, crimping, or compression connectors to ensure secure and reliable connections. Improper termination can lead to poor conductivity, overheating, and potential safety hazards. – Environmental conditions: Consider the environmental conditions in which the tinned copper power cables will be installed, such as temperature, moisture, and exposure to chemicals. Choose cables with the appropriate insulation and jacketing materials to withstand the specific environmental factors and ensure long-term reliability. – Compliance with standards: Ensure that the installation of tinned copper power cables complies with relevant industry standards and regulations to guarantee safety and performance. Following insulated sheathed power cable and guidelines helps prevent accidents, fire hazards, and other risks associated with electrical installations. Conclusion Tinned copper power cables are essential components in modern electrical systems, offering superior conductivity, corrosion resistance, and durability for various power transmission applications. These cables provide numerous advantages over traditional copper cables, making them a preferred choice for industries such as power distribution, industrial machinery, renewable energy, and more. By understanding the features, advantages, applications, and installation considerations of tinned copper power cables, electrical professionals can make informed decisions when selecting and installing these cables for their projects. With their exceptional performance and reliability, tinned copper power cables continue to play a vital role in ensuring safe and efficient power transmission in today's interconnected world.